HOW WE WORK EVERY DAY

Machinery park

Our machinery is the heart of production at SAG. This is where our high-quality products are created thanks to modern and precise devices. Reliable machines guarantee precision and efficiency as well as very high standards of workmanship. Check out the solutions we use to deliver durable and solid constructions tailored to your needs!

PRECISE HOLES

Boring machine

A boring machine plays a key role in streamlining and accelerating production processes by ensuring precise machining of large structural elements.

Boring machines are essential in the production of components that require precise machining, allowing the company to maintain the high quality of its products.

FASTER AND MORE ACCURATE

Circular saw for high-performance cutting

At SAG Sp. z o.o., which focuses on efficiency and precision, these types of saws can be used to prepare structural and steel components with high accuracy, which translates into optimised production processes. Fast cutting of larger quantities of material without compromising quality not only increases the speed of order fulfilment, but also reduces waste, which is in line with a modern approach to production and resource management.

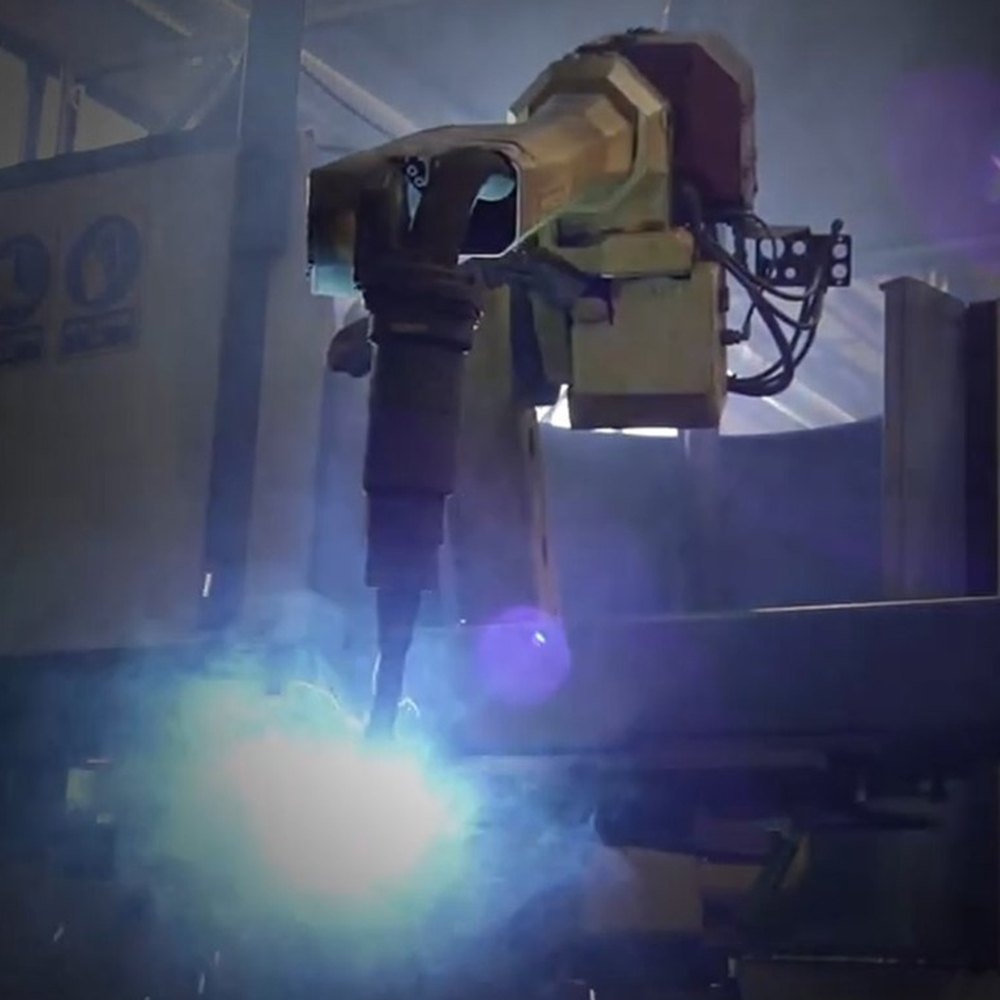

REPEATABLE PRECISION EVEN AFTER 1,000 WELDS

Welding robot

Thanks to its precision and repeatability, the Fanuc welding robot enables consistent, high-quality welds — even on complex structures. This is particularly important in mass production, where any imperfection could affect the durability of the entire product.

The welding robot can also operate in continuous mode, which allows for shorter order fulfilment times and increased productivity without overburdening employees.

The systems are compatible with modern welding methods such as MIG/MAG, TIG and submerged arc welding, which provides flexibility in adapting the process to different materials and thicknesses.

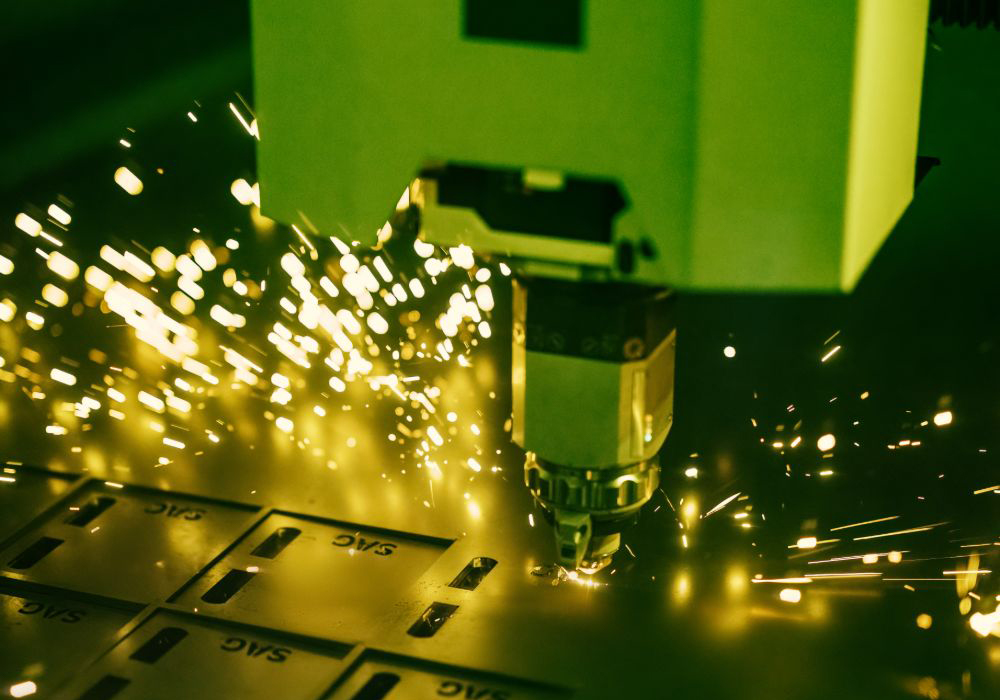

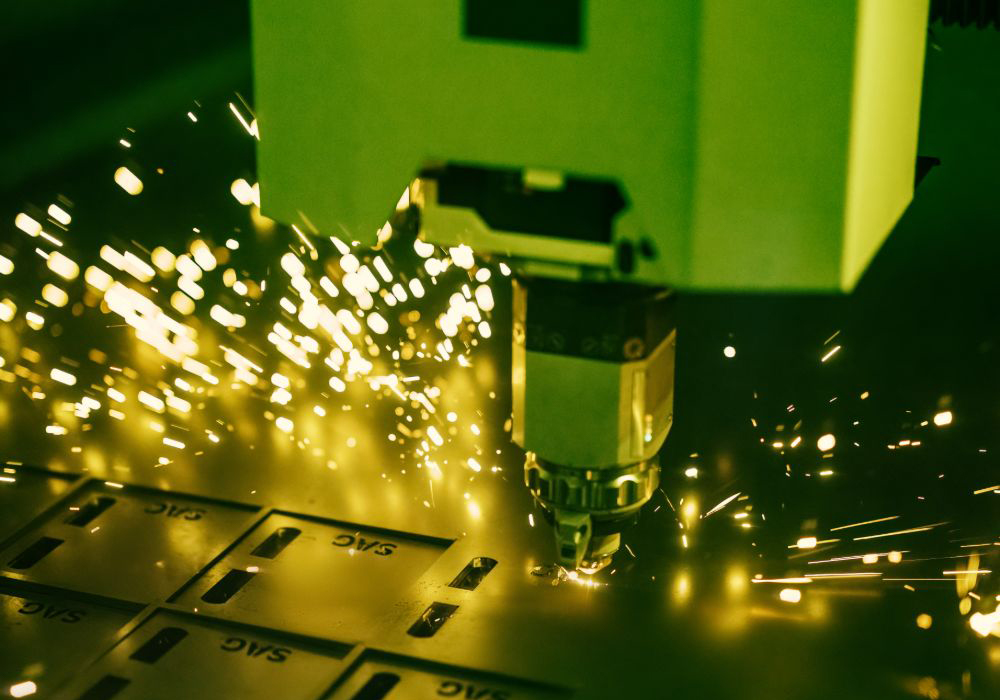

IT'S LIKE A MECHANICAL SURGEON

Laser cutting machine

In 2023, the company invested in modern machinery, including a laser cutting machine, to increase production precision and efficiency.

The laser cutter enables precise cutting of complex shapes and small holes, which is important in the production of components with high quality requirements.

Laser cutting of details from 1.5m x 3m sheets with a thickness of 0.5mm to 20mm.

THE ENORMOUS POWER OF PLASMA

Plasma cutter

Plasma cutters are typically used to cut thicker materials, but do not offer the precision of lasers. They use a concentrated plasma arc that reaches very high temperatures (even over 20,000°C), which allows for fast and precise cutting including: steel sheets and profiles used in the steel structure industry to prepare elements of specific shapes.

Gas and plasma cutting of details made of 2 m x 6 m sheets and max. thickness 150 mm.

FASTER AND MORE ACCURATE

Automatic lathes

Automatic lathes with automatic loading systems, such as the model used at SAG, play a key role in modern industrial production. Thanks to the automated machining and material feeding process, these machines enable the serial production of precision components, minimising operator involvement and increasing production efficiency.

PERFECT BENDING

Press brake

Press brakes are mainly used for bending sheet metal at precise angles. They are invaluable in the production of frames, housings, brackets and other components requiring bending at the appropriate angle. Modern CNC models allow for the programming of bending sequences, which significantly speeds up work and minimizes the risk of errors.

FAST SPEED AND REPEATABILITY

Hydraulic press

High pressure force – allows for the processing of thick and hard materials.

Precision and repeatability – modern control systems guarantee high quality in serial production.

Flexibility – quick tool change and machine adaptation to various tasks.

Assembly and pressing – hydraulic presses are ideal for assembling components by pressing, e.g. bearings, bushings or other components requiring high pressure, especially in the production of rollers.

+48 32 255 72 60

+48 32 255 72 60